DUPLEX

MC80HP UNIT + MC80 STABILIZER

CENTRAL GAS SUPPLY SYSTEM

INSTRUCTION FOR USE

CENTRAAL GASTOEVOERSYSTEEM

GEBRUIKSAANWIJZING

CENTRALGASANLÄGGNING

ANVÄNDARANVISNING

MEDISINSKE GASSALARM SYSTEM

BRUKSANVISNING

MEDICINSKE GASALARMSYSTEMER

BRUGSANVISNINGER

LÄÄKINNÄLLISET KAASUHÄLYTINJÄRJESTELMÄT

KÄYTTÖOHJE

SYSTÉM CENTRÁLNÍHO ROZVODU PLYNU

KÖZPONTI GÁZELLÁTÓ RENDSZER

GCE HEALTHCARE

EN

NL

SV

NO

DA

FI

CS

NÁVOD K POUŽITÍ

HASZNÁLATI UTASÍTÁS HU

2/136

EN

1. FOREWORD

These instructions for use cover essential information for the entire life cycle of the manifold:

• Installation,

• Operation and bank changeover,

• Alarm conditions,

• Maintenance and cleaning,

• Disposal.

GCE Medical central gas system is medical device classified as class IIb according to the Medi-

cal Device Directive 93/42/EEC.

Their Compliance with essential requirements of 93/42/EEC Medical Device Directive is based

upon EN ISO 7396-1 and EN 60601-1 standards.

2. INTENDED USE

The MC80 semiautomatic medical manifold is intended for use in hospital pipeline system

as manifold pressure regulators. Together with MC80 shall always be used alarm providing all

alarms according to standard EN ISO 7396-1.

This instruction for use details the operational and safety procedures for the MC80 manifold.

The MC80 manifold is available for Oxygen, Nitrous Oxide* and Compressed Air, it can also be

used for Carbon Dioxide*, Nitrogen, and gas blends for Medical Applications. These manifolds

are designed to operate at a maximum inlet pressure of 200 bar.**

Note: In Nitrous Oxide and Carbon Dioxide there is humidity due to the common production

methods, the mounting of a pre-heater per bank (total 2 pre-heaters per manifold) eliminates

possible working diculty of the manifold. These diculties are due to the fact that the gas,

when expanding, tends to produce ice.

Read this instruction before use of the product. Always follow this instruction!

The product shall only be used for the purpose described in this instruction!

The product must be installed by a qualified person and by compliance of all requirements of

EN ISO 7396-1 as amended!

Before use, to guarantee the safety of the patient, check the equipment and the accessories

used with the product, so that data and performance comply with the intended use of the

product!

The product must not, under any circumstances be modified by other than the manufacturer!

The product must not be used for dierent gas than stated on the label.

* Manifold shall be installed in room with minimal temperature of 10 °C.

** Maximum service pressure of 200 bar means for use with cylinders filled to a maximum set-

tled pressure of 200 bar (at 15 °C). At higher temperatures cylinder pressure will exceed 200 bar

(developed pressure). For example developed pressure for oxygen at 50 °C is 240 bar.

The marking to be read on the regulator or manifold product label refer to max settled cylin-

der pressure not developed cylinder pressure, this should match the pressure marking on the

cylinder.

ENGLISH

INSTRUCTION FOR USE: DUPLEX

3/136

EN

3. OPERATIONAL, TRANSPORT AND STORAGE SAFETY

REQUIREMENTS

KEEP THE PRODUCT AND ITS ASSOCIATED EQUIPMENT AWAY FROM:

• heat sources (fire, cigarettes, ...)

• flammable materials,

• oil or grease (especially be careful if hand cream is used),

• water,

• dust.

The product and its associated equipment must be prevented from falling.

Always maintain oxygen cleanliness standards.

Use only the product and its associated equipment in a well ventilated area.

Before initial use the product shall be kept in its original packaging.

GCE recommends use of the original packaging (including internal sealing bag and caps) if the

product is withdraw from operation (for transport, storage).

The product owner or user must ensure that during the product life cycle transport and storage

environmental conditions are in accordance with the above “Safety instruction” section require-

ments, in order to maintain product integrity and cleanliness. Statutory laws, rules and regula-

tions for medical gases, accident prevention and environmental protection must be observed.

OPERATING CONDITIONS STORAGE AND TRANSPORT

CONDITIONS

MIN MAX MIN MAX

+10 °C +60°C -30 °C +70 °C

10 % 100 % 20 % 70 %

600 mbar 1200 mbar 600 mbar 1200 mbar

It’s very important to assure access to this device only for qualified person – possibility of

misuse.

3.1.OPERATIONAL SAFETY

The panel described in this manual is for cylinder gases and the following general practices are

our recommendations for the safe, ecient storage and use of such compressed gases.

3.1.1.CYLINDER STORAGE

Storage area shall be designed according to valid standard, here are some recommendations:

• Well ventilated with weather protection.

• Free from fire risk. Keep away from sources of heat and ignition. Designated as a ‘no smoking’

area. Clearly marked as a gas store with appropriate hazard warning signs (e.g. flammable,

toxic, etc.).

• Kept clear with access restricted to authorised personnel.

• Provided with appropriate safety/emergency equipment (e.g. Fire extinguisher, breathing

apparatus etc.)

4/136

EN

Compressed gas cylinders (in storage) should be;

• Standing upright where designed for this.

• Properly secured to prevent overturning.

• Fitted with valve protection devices (e.g. caps, guards etc.) where supplied.

• Segregated in the storage area according to the various categories (e.g. flammable, oxidant

etc.).

• Segregated in the storage area according to content and clearly designated full or empty.

• Managed to ensure that the oldest stock is used first.

• Checked periodically for general condition.

Personnel: (who enter the storage area) should be;

• Responsible and competent to maintain the gas store and its contents as above.

• Familiar with and able to identify the contents of the gas containers and their potential hazards.

3.1.2.EMERGENCY PROCEDURES:

An emergency results from:

• A fire near or in the cylinder manifold room.

• An unintended leak of gas from the cylinders or pipeline.

• Some other potential or actual incident which will aect the integrity of the manifold installation.

Procedure to follow:

• Raise the alarm and notify a supervisor and/or call the fire brigade.

• Evacuate all personnel from the immediate danger area.

In case of fire, remove all cylinders:

• Close the cylinder valve(s) on all cylinder(s)/ cylinder bundles.

• Close the bank isolating valve(s).

• Disconnect the high pressure hoses.

• Move the cylinders to a safe area using a suitable cylinder trolley.

In the case of an uncontrollable escape of gas:

• Open the doors to the manifold room to ventilate the area.

• Do not introduce sources of ignition into the area.

It is important that ready access to these instructions is given at all times and that the mani-

fold is not put into operation until the operator is fully familiar with its functions, controls and

safety precautions.

It is the duty of all employers to provide such information, training and supervision according

to national standards as is necessary to ensure so far as is reasonably practical the health and

safety at work of its employees.

4. PERSONNEL INSTRUCTIONS

The Medical Devices Directive 93/42/EEC states that product provider must ensure that all per-

sonnel handling the product are provided with the operating instructions & performance data.

Do not use the product without properly familiarization of the product and its safe operation

as defined in this Instruction for use. Ensure user is aware of particular information and knowl-

edge required for the gas in use.

5/136

EN

5. PRODUCT DESCRIPTION

The manifolds covered by these instructions are designed to allow equal numbers of cylinders

to be manifold together to give an operating bank and a reserve bank. The operating bank will

deliver gas to the manifold pressure regulator until the cylinders are exhausted. At that point the

supply will switch to the reserve bank and the exhausted bank can be replenished. The object

is to give uninterrupted gas supply.

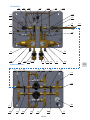

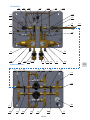

The MC80 semiautomatic (DUPLEX) medical manifold contains three parts: HP UNIT, STABI-

LIZER. According to product variant you obtain one or all parts of MC80.

HP UNIT STABILIZER

HP UNIT

The manifold MC80 contains High pressure unit. More info about High pressure unit is men-

tioned below.

STABILIZER

The manifold MC80 contains Stabilizer. More info about Stabilizer is mentioned below.

GAS ALARM

The manifold MC80 contains Gas Alarm. For more info see Instruction for use for Gas Alarm.

I1, I2 INLET CONNECTION

The HP unit contains left and right side inlet collection pipes. There are thread connections that

fits to the high pressure hoses.

I3 INLET OF STABILIZER

The Stabilizer contains one inlet connections. There is swivel nut with internal thread connec-

tion.

P5, P6 CONNECTION

The Stabilizer contains two connections which can be used as inlet of the Stabilizer, for example

for LOX connection.The connections are with swivel nuts and internal thread connections.

F1, F2 FILTERS

The manifold contains two 100 microns high pressure filters with integrated non-return valves

which are installed on the inlet of the HP unit. These filters are easy to maintain.

V1, V2 INLET SHUT OFF VALVES

The manifold contains two inlet shut o valves which are for opening and closing main high

pressure supply from the gas cylinders to the left and right side of the HP unit.

V3, V4 SHUT OFF VALVES

The HP unit contains two shut o valves. The shut o valves are used together with V1 and V2

during service and repair.

V5 SHUT OFF VALVE

The HP unit contains one shut o valve which is used during service and repair of the pilot regu-

lator. The Shut o valve is used for closing pilot pressure for high pressure regulators.

6/136

EN

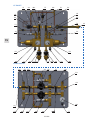

HP UNIT

STABILIZER

V5

R3

T3

S1

R1

M1 T1 V1 F1 I1 I2 F2 V2 T2 M2

R2

S2

T4

P2

V4

P1 V3 M3 T5 V6 E1 P3

P6 V8 S4 R6 P8 V10

V10V10 T7

M4

O2

P9

V9P7

R5

E2

V7P5

I3

O1

S3

7/136

EN

V6 SWITCH VALVE

The HP unit contains one switch valve which is used for changing the operating side of the

pilot regulator. (The pilot regulator gives extra power to the HP regulator on the operating side.)

V7, V8 SHUT OFF VALVES

The Stabilizer contains two shut o valves. The shut o valves are switching the gas flow be-

tween regulator R5 and R6 together with shut o valves V9 and V10. The valves are used dur-

ing service, to give uninterrupted gas supply.

V9, V10 SHUT OFF VALVES

The Stabilizer contains two shut o valves. The shut o valves are switching the gas flow be-

tween regulator R5 and R6 together with shut o valves V7 and V8. The valves are used during

service, to give uninterrupted gas supply.

R1, R2 HIGH PRESSURE REGULATORS

The HP unit contains two high pressure regulators. The regulators are reducing the pressure

from high pressure to the intermediate pressure.

R3 PILOT REGULATOR

The HP unit contains one pilot regulator. The regulator is used for increasing the intermediate

pressure from one of the HP regulators.

R5, R6 LINE REGULATORS

The Stabilizer contains two line pressure regulators. The regulators are reducing the pressure

from intermediate pressure to the distribution pressure. Information about pre-setting’s of the

product you can find in testing report included to the product delivery.

S1, S2 SAFETY VALVES

The manifold contains two intermediate pressure safety valves, one on each side. When the

pressure increase up to pre-set level the safety valve will activate and gas will purge out

through the exhaust pipe.

S3, S4 SAFETY VALVES

The stabilizer contains two distribution pressure safety valves, one on each side. When the

pressure is increasing up to pre-set limit the safety valve will activate and gas is purging out

through the exhaust pipe.

M1, M2 HIGH PRESSURE GAUGES

The HP unit contains two high pressure gauges. The gauges are showing the inlet pressure

from the collecting pipes.

M3 INTERMEDIATE PRESSURE GAUGE

The HP unit contains one intermediate pressure gauge. The gauge is showing the intermediate

pressure from the HP unit.

M4 LOW PRESSURE GAUGE

The Stabilizer contains one low pressure gauge. The gauge is showing the distribution pressure

from the Stabilizer.

T1, T2 HIGH PRESSURE SENSOR

High pressure sensors are installed on the inlet of the HP unit. Main function of high pres-

sure sensors is to supervise leakage on reserve side and send information to the alarm. When

leakage on reserve side is detected by pressure drop, the alarm starts to inform the technical

personal.

T3, T4 PRESSURE SENSOR

The HP unit contains two pressure switches. A main function of high pressure switches is

checking which side is operation and which side is reserve.

T5 PRESSURE SENSOR

The HP unit contains one sensor which is checking intermediate pressure. Main function of the

pressure sensor is checking upper limit of the intermediate pressure. If the pressure is too high,

the sensor will send information to the alarm unit.

T7 PRESSURE SENSOR

The Stabilizer contains one low pressure sensor which is installed in the outlet block. Main func-

tion of the pressure sensor is to check correct distribution pressure. If the pressure is so low or

high, the sensors will send information to the alarm unit.

8/136

EN

E1 EVACUATION PIPE

The HP unit contains evacuation pipes, which are exhaust pipes from the intermediate pressure

safety valves.

E2 EVACUATION PIPE

The Stabilizer contains evacuation pipes which are exhaust pipes from distribution pressure

safety valves.

O1 OUTLET OF HP UNIT

The HP unit have one outlet with thread connection. On the outlet of HP unit it is possible to

mount shut o valve and outlet pipe. The Shut o valve and outlet pipe are included only in

DUPLEX (manifold with HP unit, Stabilizer and Alarm).

O2 OUTLET OF STABILIZER

The Stabilizer has one outlet connection. The connection is with swivel nut and internal thread

connection.

P9 CONNECTION

The Stabilizer contains one connection which can be used as outlet of the Stabilizer. The con-

nection is with swivel nut and internal thread connections.

P1, P2 CONNECTION

The HP unit contains two connections which are used during service and repair, for example

testing safety valves.

P3 CONNECTION

HP unit contains one connection which is used during service and repair, for example digital

pressure device.

P7, P8 CONNECTION

The Stabilizer contains two connections which are used during service and repair, for example

testing safety valves. P11 P12

V11

V13

H1 H2

V14

V12

The MC80 semiautomatic medical manifold can be delivered with HP accessories. The ac-

cessories contain parts for connecting gas cylinders. Basic parts of accessories are in picture

bellow.

P11, P12 COLLECTING PIPES

Collecting pipes are used for connecting gas cylinders to the manifold. Two equal parts one left

and one right of these pipes should be included to the HP unit.

9/136

EN

V11, V12 PURGE SHUT OFF VALVES ON COLLECTING PIPE

Through the purge valves it is possible to ventilate the high pressure collecting pipes on the

empty side before removing high pressure hoses from the cylinders. The purge valve are also

used for cleaning the collecting pipes before opening the inlet shut o valves and supplying

gas to the manifold.

V13, V14 INLET SHUT OFF VALVES ON COLLECTING PIPES

If collecting pipes are used, inlet shut o valves and non-return valves shall be included. Shut

o valves stops the gas supply between each cylinder and the collecting pipes.

H1, H2 CYLINDERS HOLDERS

The accessories can contain cylinders holders. Cylinder holders are used for prevention of the

gas cylinders from falling over.

6. INSTALLATION

It is necessary that an installer of the product is trained and has an appropriate licence ac-

cording to national standards. It is outside the scope of these operating instructions to give

detailed guidance on installations.

The installation must conform to the standard MEDICAL GAS PIPELINE SYSTEMS EN ISO

7396-1 as amended. All tests according this standard have to be fulfilled.

When working with medical gases it is essential that no oil or grease come into contact with

the gas. This means that hands, tools and work clothes be free from oil or grease before any

work is undertaken. Components used for service must be gas compatible. For oxygen ser-

vice must also be degreased and although they will reach you in this condition care must be

taken during storage and handling.

6.1.WALL FIXING

Positioning of the manifold, please consult with responsible central gas system designer. Mount

the manifold at the height to suit either cylinders or cylinder bundles.

The holes to use for mounting the manifold are shown in Fig. 3.

Be aware that only upper screw is holding the entire weight of the manifold. Size of used

screws shall conform to total load.

Fig. 3

10/136

EN

6.2.FITTING OUTLET CONNECTION

Solder diameter pipe 22 mm.

6.3.FITTING SAFETY VALVE AND PURGE OUTLETS

Fittings for safety valves outlet pipes are mechanical joints connections, pipe diameter 10mm,

for the HP unit and pipe diameter 15mm, for the Stabilizer assembly. The pipes from safety

valves can (by use of a T-coupling) be soldered together and have a common outlet outside

the building.

6.4.FITTING TAILPIPES / HIGH PRESSURE HOSES / COLLECTING

BRANCH

• Screw tailpipes / high pressure hoses from cylinders or cylinder bundles / collecting branches

together and then onto the inlet connections on the manifold. Ensure that both the shut-o

valves (V1 & V2) and the purge valves (V11 & V12) are in the closed position.

• Open one cylinder from one bank SLOWLY.

• Check connection between tailpipe and inlet connection for leakage using a 0.5% teepol /

water solution.

• If no leakage is detected, open remaining cylinders slowly from that bank. Repeat operation

on opposite bank.

Note: if leakage occurs between tailpipe/high pressure hose/collecting branch and inlet con-

nection check to see if sealing’s or washers are fitted correctly or missing. If it is damaged

change the sealing and try again.

6.5.FITTING TO SOURCE OF ELECTRICITY

Any work with electric wiring must be carried out by a trained person with an appropriate

licence according to national standards.

Act upon instruction for use for gas alarm.

The product must be grounded through the anchor bolt at the protective earth label.

7. OPERATION AND BANK CHANGE OVER

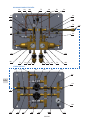

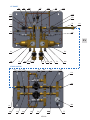

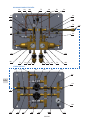

The diagram below depicts the controls for normal operation of the MC80 manifold.

7.1.START UP THE MANIFOLD

When the manifold is completely installed and the parameters are checked.

• Check both shut o valves V1 & V2 are closed.

• Check both shut o valves V13 & V14 are closed.

• Check both purge valves V11 & V12 are closed.

• Check that the valves (V3 & V4), V5, O1, (V7 & V9) or (V8 & V10) are in open position.

• Open the cylinder/cylinder bundle valves slowly.

• Open valve (V13 & V14) and (V1 & V2) slowly, and gas will start to supply through the outlet

connection O2. The cylinder pressures can be read on the gauges M1 & M2 and the outlet

distribution pressure on gauge M4.

• Decide by turning the switch V6, if right or left bank of cylinders should start to supply. Always

start supply from the bank that has the lowest pressure.

If liquid oxygen tank is used as primary source of supply, connection P5 or P6. The inlet valve

from LOX tank shall be open and the parameter settings shall be according to instruction for

LOX.

• Check all connections for leakage using a 0.5% teepol / water solution.

• While gas is flowing the pressure in the operating side will fall. This will be indicated on the

inlet gauges M1 or M2.

11/136

EN

V5

R3

T3

S1

R1

M1 T1 V1 F1 I1 I2 F2 V2 T2 M2

R2

S2

T4

P2

V4

P1 V3 M3 T5 V6 E1 P3

O1

HP UNIT

STABILIZER

P6 V8 S4 R6 P8 V10

V10V10 T7

M4

O2

P9

V9P7

R5

E2

V7P5

I3

S3

12/136

EN

7.2.BANK CHANGE OVER FOR MC80 HP

At a pre-determined pressure set of the manifold regulators of 8 bar (intermediate pressure

minus 4 bars) the reserve bank will take over from the near empty bank of cylinders. You will

have an alarm “Change of operating side” at inlet pressure lower than 12 bar. It is indicated by

pressure transmitters.

7.2.1.LEFT HAND LH SIDE EMPTY

• The inlet pressure gauge M1 on the left-hand side is indicating exhausted cylinders, so the

left-hand bank of cylinders needs to be replaced.

• Close shut-o valve V1 and the isolating valves on the empty cylinders or cylinder bundles.

• Open purge valve V11 to vent any excess gas within the high pressure hose.

• Close purge valve V11 and disconnect high pressure hose from cylinders or cylinder bundles.

• Re-place empty cylinders with full ones.

• Re-connect high pressure hose to cylinders or cylinder bundles. Use new gaskets, lubricated

with grease approved for high pressure oxygen up to 250bar (like lubricant).

• Open cylinder valves slowly and leak test joints with 0.5% teepol in water solution.

• Open shut-o valve V1 and read the full content of the new cylinders on the inlet gauge M1.

• Change the position of the switch V6, to give normal operation to right-hand side (switch valve

pointing to the right).The alarm condition “RESERVE CONN.” will hereby be cancelled.

• The left hand side is now the reserve bank with full cylinders.

7.2.2.RIGHT HAND RH SIDE EMPTY

• The inlet pressure gauge M2 on the right-hand side is indicating exhauste cylinders, so the

right-hand bank of cylinders needs to be replaced.

• Close shut-o valve V2 and the isolating valves on the empty cylinders or cylinder bundles.

• Open purge valve V12 to vent any excess gas within the high pressure hose.

• Close purge valve V12 and disconnect high pressure hose from cylinders or cylinder bundles.

• Re-place empty cylinders with full ones.

• Re-connect high pressure hose to cylinders or cylinder bundles. Use new gaskets, lubricated

with grease approved for high pressure oxygen up to 250bar (like lubricant).

• Open cylinder valves slowly and leak test joints with 0.5% teepol in water solution.

• Open shut-o valve V2 and read the full content of the new cylinders on the inlet gauge M2.

• Change the position of the switch V6, to give normal operation to left-hand side (switch valve

pointing to the left). The alarm condition “RESERVE CONN.” will hereby be cancelled.

• The right hand side is now the reserve bank with full cylinders.

7.3.SHUT DOWN

For short term (hours) shutdown close shut-o valves V1 & V2 and/or V13 & V14 and/or O1.

For long term (days) shutdown close shut-o valves V1 & V2 and/or V13 & V14 and the cylinder

isolating valve.

8. ALARM CONDITIONS

8.1.ALARM PROCEDURE

On signal of alarm condition the audible and the appropriate visual indicator is illuminated on

the Gas Alarm unit. The alarm condition should be recorded and the necessary action taken, as

detailed in the sections below.

8.2.STATUS INDICATED BY GAS ALARM

Always use instruction for the Gas Alarm.

13/136

EN

8.2.1.LEAKING RESERVE SIDE RIGHT LEAKAGE OR LEFT LEAKAGE

The alarm starts in following situations:

Reserve side pressure is too low

• Allocate the leakage using leak detecting spray. Isolate the leaking area and do repair/change

component or washer.

• Check that the audible and visual alarms on the the Gas Alarm have been cancelled.

8.2.2.CHANGE OF OPERATING SIDE RESERVE CONN.

The alarm starts in following situations:

The supplying side is empty

• Replace the empty cylinders with full cylinders as described in chapter 7.

• Check that the audible and visual alarms on the the Gas Alarm have been cancelled.

8.2.3.HIGH INTERMEDIATE PRESSURE

The alarm starts in following situations:

Intermediate pressure is too high

• Check that the manifold regulator R1 & R2 outlet pressure is as preferred. If not, isolate the

regulators by closing valve V3 or V4 and check one regulator at a time. Start with the regulator

on reserve side, relief the pressure by the safety valve S1 & S2 and check if the pressure

increases again. Change operating side and make the same test with the other regulator.

• If you shortly after resetting the regulator have the same alarm condition again, the regulator

most likely has internal leakage. Contact authorised service for replace the regulator with a

new or refurbished unit.

• Check that the audible and visual alarms on the Gas Alarm have been cancelled.

8.2.4.HIGH DISTRIBUTION PRESSURE OP.PRESSURE HIGH

The alarm starts in following situations:

Distribution pressure is too high

• Check that the distribution pressure is as preferred. If not, isolate the regulators R5 & R6 by

closing valve V9 or V10 and check one regulator at a time. Start with the regulator on reserve

side, relief the pressure by the safety valve S3 & S4 and check if the pressure increases again.

Change operating side and make the same test with the other regulator.

• If you shortly after resetting the regulator have the same alarm condition again, the regulator

most likely has internal leakage. Contact authorised service for replace the regulator with a

new or refurbished unit.

• Check that the audible and visual alarms on the Gas Alarm have been cancelled.

8.2.5.LOW DISTRIBUTION PRESSURE OP.PRESSURE LOW

The alarm starts in following situations:

Distribution pressure is too low

• Check the high pressure gauges M1 & M2, if the valves V13 & V14 and cylinders valves are

open, if the cylinders are not empty or if there is a leakage. In this case replace cylliders or

make corrections on collection pipelines.

• Check the intermediate pressure gauges M3, if the valves V1 & V2 and V3 & V4 valves are

open or if there is a leakage. In this case follow procedure as Intermediate pressure is too

high.

• Check the distrubution pressure gauge M4, if the valve V7 & V8 is in correct position or

if there is a leakage. In this case reset regulators R5 & R6 one at a time by releasing the

pressure with the safety valves S3 & S4, start with the reserve side. Check if the pressure

comes back to normal, if not increase the distribution pressure by turning the regulator R5

& R6 screw and check again. If the distribution pressure is still low, contact authorised service

for replace the regulator with a new or refurbished unit.

• Check that the audible and visual alarms on the Gas Alarm have been cancelled.

14/136

EN

9. ROUTINE MAINTENANCE INSTRUCTION

Service shall be carried out only by authorised person according to national standards.

Use only original components. Contact GCE for further information about repair procedures.

9.1.THE FOLLOWING ROUTINE CHECKS SHOULD BE MADE WHEN

CHANGING CYLINDERS:

• Check all valves for correct operation and leak test using a 0.5% teepol in water solution.

• Check pipe work for leaks using a 0.5% teepol in water solution.

• Check that all notices are in place, can be easily read and are not obstructed from view.

• Inspect the vicinity of cylinders for anything introduced since last inspection, which could

aect the continuing safe operation of the manifold.

9.1.1.GENERAL MAINTENANCE SHOULD BE UNDERTAKEN IN ACCORDANCE

WITH A PLANNED MAINTENANCE SCHEDULE, WHICH SHOULD INCLUDE THE

FOLLOWING ITEMS:

• Leak test all joints using a 0.5% teepol in water solution.

• Examine mounting frames and cylinder securing chains for damage deterioration and security

of attachment.

• Examine tailpipes/high pressure hoses for damage and security of attachment.

• High pressure hoses should receive particular attention to ensure they are secure, not worn

or otherwise weakened.

• Components with limited lifetimes, such as high pressure hoses, should be subjected to a

routine replacement programme.

• Filters are in good condition and not blocked. Filter elements may need to be cleaned or

renewed and pipelines may need to be blown through to remove foreign material.

• Valves to be used in normal or emergency operation are accessible and easy to operate.

Valves at service point’s outlets and purge valves should be checked for gas tightness.

• No item of equipment is overdue for any periodic inspection/test which may be applicable.

• The setting and operation of regulators is satisfactory.

• The necessary safety devices and instruments are fitted, are of the correct type and do not

show signs of deterioration or unauthorised interference.

• The equipment downstream of the outlet point is suitable for further service.

• Check connecting nuts and seating faces are undamaged.

• Check gauges operate smoothly and zero correctly.

• Check isolating valves for closure tightness and gland leakage.

• The gas manifold room must always remain thoroughly clean. Materials other than those

required for operating the manifold must not be stored in the room.

• Check that all ventilation grills are free from obstruction and that the extraction system (when

installed) is functioning correctly.

• Ensure that all restrictions on smoking and open fire are strictly enforced.

• Replace all worn or damaged parts with original spare parts. Remember that gaskets, o-rings

and sealing surfaces must be clean and free from damage to work eectively.

9.1.2.SAFETY NOTEAS PART OF THE PLANNED MAINTENANCE SPECIAL

CHECKS SHOULD BE MADE TO ENSURE:

All changes (including removal and addition of parts) and extensions conform to the right code

of practice.

Changes in the vicinity of the installation do not aect the safety of the operation e.g. proximity

of electricity to fuel gases, oils and combustibles near to oxygen, illicit use of a pipeline as an

electrical conductor or as a support for other items.

15/136

EN

10. SCHEME OF EXAMINATION

EQUIPMENT EXAMINATION

INTERVAL GUIDELINES OF WRITTEN SCHEME

1. High pressure

hoses

Examine when

changing

cylinders.

a. Replace with new hose, every 5 years.

b. Replace gaskets when changing

cylinders.

c. Record replacement.

2. Safety Relief Valve 1 year a. Visual, external examination.

b. Check the functions.

c. Record all details of examination.

3. Regulator 1 year a. Replace with new or manufacturer’s

refurbished unit.

b. Check the functions.

c. Record all details.

4. Non return valves 1 year a. Function and Filter testing.

b. Replace seals/glands/o-rings, if needed.

c. Leakage test.

d. Record all details of examination.

5. Valves 1 year a. Functional test

c. Record all details of examination.

6. Manifold 1 year a. Visual, external examination.

b. Leakage test.

c. Record all details of examination.

7. Filters 1 year a. Replace with new or manufacturer’s

refurbished unit.

b. Leakage test.

c. Record all details.

11. ACCESSORIES

Contact supplier of the system or GCE dealer for spare part lists. Use only authorised parts.

Use only GCE original spare parts!

12. CLEANING OF EXTERNAL PARTS

Remove dirt with a soft cloth damped in oil free oxygen compatible soap water and rinse with

clean water. If other cleaning solutions are used, check that they are not abrasive and that they

are compatible with: Cu, Fe, Al alloy, brass, plastic materials of components, labels and gas.

Do not use cleaning solutions containing ammonia!

Do not immerse in water or any liquid.

Do not clean electrical connections when the power is on. Make sure the connections are dry

before turning power back on.

16/136

EN

13. LIFETIME AND DISPOSAL

13.1.LIFE TIME AND WASTE MANAGEMENT

The maximum life time of the product is 10 years at compliance of Examination schedule (chap-

ter 10). At the end of the product’s life time, the product must be withdrawn from service.

The owner of the device shall prevent the reuse of the product and handle the product in com-

pliance with “Directive of European Parliament and Council 2008/98/EC on waste“.

In accordance to Article 33 of REACH GCE, s.r.o. as responsible manufacturer shall inform all

customers if materials containing 0.1% or more of substances included in the list of Substance

of Very High Concern (SVHC).

The most commonly used brass alloys used for bodies and other brass components contain

2-3% of lead (Pb), EC no. 231-468-6, CAS no. 7439-92-1. The lead will not be released to the gas

or surrounding environment during normal use. After end of life the product shall be scrapped

by an authorized metal recycler to ensure ecient material handling with minimal impact to

environment and health.

To date we have no information that indicates that other materials containing SVHC of concen-

trations exceeding 0.1% are included in any GCE product.

13.2.MANUFACTURING DATE

The manufacturing date is included in product serial number which is marked on back plate.

Serial number composition is the following: YYMMXXXXX

Y: 2 last numbers of the year of manufacture

M: month of manufacture

X: production number

The perforation in the device label indicates the year when the equipment has to be disposed

o.

13.3.REPAIR

Repair activities of GCE product must be carried out by GCE or authorized repair centers.

Contact GCE for further information about service available in your area.

All labels on the equipment must be kept in good, legible condition by the owner and the

user during the entire product life time.

Use only genuine GCE components.

13.4.DISPOSAL AT THE END OF THE PRODUCT’S LIFE TIME,

Product must be recycled in compliance with the national and local regulations.

No part contains any chemical materials burdensome environment.

14. GLOSSARY

Consult instruction for use Take back equipment for

recycling. Do not dispose

equipment into unsorted

municipal waste

Caution!

Keep away from heat and

flammable materials. Suitable for Hospital care use

Keep away from oil and

grease!

Take back battery for recy-

cling

Humidity limit SN Serial number

17/136

EN

APPENDIX:

Nr 1 - Technical specification and performance data

Nr 2 - Testing protocol

MANUFACTURER:

GCE, s.r.o. Tel: +420 569 661 111

Zizkova 381 Fax: +420 569 661 602

583 01 Chotebor http://www.gcegroup.com

Czech Republic © GCE, s.r.o.

Temperature limit REF Catalogue number

Keep dry! LOT Batch code

Date of manufacture Manufacturer

Use by date Fragile, handle with care

Inlet parameter Outlet parameter

P1Inlet pressure range P2Outlet pressure

P4

Max outlet pressure (closing

pressure) QOutlet flow

Service or disposal date The

serial number indicates the

year product has to undergo

the overall maintenance ac-

tivities or has to be disposed

o. Refer to the serial number

note to determine the Overall

maintenance or disposal.

Weight of product

Atmospheric pressure limit

The protective earth label

15. WARRANTY

The Standard Warranty period is two years from date of receipt by the GCE Customer (or if this

is not known 2 years from time of the product manufacture shown on the product).

The standard warranty is only valid for products handled according to Instruction for use (IFU)

and general industry good practice and standards.

18/136

NL

1. VOORWOORD

Deze gebruiksaanwijzing bevat belangrijke informatie voor de volledige levensduur van het

spruitstuk:

• Installatie,

• Gebruik en wisseling van rijen,

• Alarmtoestanden,

• Onderhoud en reiniging,

• Afvoer.

Het GCE medisch centraal gassysteem is een medisch apparaat dat is ingedeeld in klasse IIb

volgens de Richtlijn Medische Apparatuur 93/42/EEG.

De naleving van belangrijke eisen uit Richtlijn Medische Apparatuur 93/42/EEG is gebaseerd

op de normen EN ISO 7396-1 en EN 60601-1.

2. BEOOGD GEBRUIK

Het MC80 semi-automatische medische spruitstuk is bedoeld voor gebruik in pijpleidingen in

ziekenhuizen als verdeelstukdrukregelaars. In combinatie met de MC80 moet altijd een alarm-

systeem worden gebruikt dat alarmen afgeeft overeenkomstig de norm EN ISO 7396-1.

Deze gebruiksaanwijzing beschrijft de bedienings- en veiligheidsprocedures voor het MC80-

spruitstuk. Het MC80-spruitstuk is beschikbaar voor zuurstof, stikstofoxide* en perslucht. Het

kan ook worden gebruikt voor koolstofdioxide*, stikstof en gasmengsels voor medische toe-

passingen. Deze spruitstukken zijn ontworpen om te worden gebruikt bij een maximale inlaat-

druk van 200 bar.**

Opmerking: In stikstofoxide en koolstofdioxide is vocht aanwezig vanwege de gebruikte pro-

ductiemethoden. Door voor elke rij een voorverwarmer te monteren (in totaal twee voorver-

warmers per spruitstuk) wordt de correcte werking van het spruitstuk gewaarborgd. Dit prob-

leem wordt veroorzaakt door het feit dat het gas bij het uitzetten tot ijsvorming kan leiden.

Lees deze gebruiksaanwijzing voordat u het product gaat gebruiken. Neem altijd de aanwij-

zingen in acht!

Het product mag uitsluitend worden gebruikt voor het doel dat in deze gebruiksaanwijzing

wordt vermeld!

Het product moet worden geïnstalleerd door een gekwalificeerde persoon en met inachtne-

ming van alle eisen uit EN ISO 7396-1 zoals geamendeerd!

Om de veiligheid van de patiënt te garanderen, moeten vóór het gebruik de apparatuur en

accessoires bij het product worden gecontroleerd, zodat de gegevens en prestaties overeen-

komen met het beoogd gebruik van het product!

Het product mag in geen geval worden aangepast door iemand anders dan de fabrikant!

Het product mag uitsluitend worden gebruikt voor het gas dat wordt vermeld op het etiket.

Aeeldingen in deze gebruiksaanwijzing dienen alleen ter informatie. Aankelijk van de

variant van het product kan het echte product er ietwat anders uitzien en mogelijk behoren

sommige van de hieronder beschreven onderdelen niet tot de levering. Raadpleeg altijd bij-

lage nr. 1 voor technische gegevens.

* Spruitstuk moet worden geïnstalleerd in een ruimte met een minimale temperatuur van 10°C.

** De maximale bedrijfsdruk van 200 bar geldt voor het gebruik van cilinders die zijn gevuld tot

een maximale druk van 200bar (bij 15°C). Bij hogere temperaturen zal de cilinderdruk boven

200bar komen (ontwikkelde druk). De ontwikkelde druk bij 50°C bijvoorbeeld is 240bar.

De markering op het productetiket van de regelaar of het spruitstuk betreft de maximale cilin-

derdruk; deze waarde moet overeenkomen met de drukmarkering op de cilinder.

NEDERLANDS

GEBRUIKSAANWIJZING: DUPLEX

19/136

NL

3. VEILIGHEIDSEISEN VOOR GEBRUIK, TRANSPORT EN OP

SLAG

PRODUCT, MET INBEGRIP VAN TOEBEHOREN, WEGHOUDEN VAN:

• bron van warmte (vuur, sigaretten, …),

• brandbare materialen,

• olie of vet, (wees voorzichtig met het gebruik van handcrème )

• water,

• stof.

Product, met inbegrip van toebehoren, moet worden veiliggesteld tegen omvallen, omkeren

of vallen.

Alle voorschriften en bepalingen voor zuurstofzuiverheid moeten worden nageleefd.

Gebruik het product en de bijbehorende apparaten alleen in goed geventileerde ruimtes.

Bij het eerste gebruik moet het product in haar originele verpakking zitten. In het geval dat het

product uit de roulatie gehaald wordt (voor vervoer, opslag) adviseert GCE de originele verpak-

king te gebruiken (inclusief de inwendige vulmaterialen).

Bij het gebruik van medische gassen moeten de nationale wetten, bepalingen en voorschriften

voor medicinale gassen, veiligheidseisen ongevallenpreventie en milieubescherming worden

nageleefd.

De eigenaar en/of gebruiker van het product moet ervoor zorgen dat gedurende de levensduur

van het product de transport- en opslagomstandigheden conform de eisen uit het gedeelte

‘Veiligheidsinstructie’ hierboven zijn om te waarborgen dat het product intact en schoon blijft.

GEBRUIKSVOORWAARDEN VOORWAARDEN VOOR VERVOER EN

OPSLAG

MIN MAX MIN MAX

+10 °C +60°C -30 °C +70 °C

10 % 100 % 20 % 70 %

600 mbar 1200 mbar 600 mbar 1200 mbar

Het is erg belangrijk dat de toegang tot dit apparaat wordt beperkt tot alleen gekwalificeerde

personen om de mogelijkheid van niet-beoogd gebruik uit te sluiten.

3.1.GEBRUIKSVEILIGHEID

Het paneel dat in deze handleiding wordt beschreven, dient voor cilindergassen en de volgen-

de algemene methoden zijn onze aanbevelingen voor het veilig, eciënt opslaan en gebruiken

van dergelijke gassen onder druk.

3.1.1.OPSLAG VAN CILINDERS

De opslagruimte moet worden afgestemd op geldige normen. Hier zijn enkele aanbevelingen:

• Goed geventileerd met bescherming tegen weersinvloeden

• Geen risico op brand Uit de buurt van warmte- en ontstekingsbronnen Aangeduid als een

‘roken verboden’-ruimte Duidelijk gemarkeerd als een locatie voor de opslag van gas(cilinders)

met bijbehorende waarschuwingsbordjes (bijv. ‘ontvlambaar’, ‘giftig’, enz.)

• Alleen toegankelijk voor geautoriseerd personeel

• Voorzien van geschikte veiligheids-/hulpapparatuur (bijv. brandblussers,

ademhalingsapparatuur, enz.)

20/136

NL

Opgeslagen gascilinders moeten:

• Rechtop staan als ze hiervoor zijn ontworpen

• Stevig worden vastgezet om te voorkomen dat ze omvallen

• Zijn uitgerust met klepbeveiligingen (bijv. doppen, beschermkappen, enz.) indien deze zijn

geleverd

• Apart worden opgeslagen overeenkomstig de verschillende categorieën (bijv. ontvlambaar,

oxiderend, enz.)

• Apart worden opgeslagen op basis van de inhoud en duidelijk worden gemarkeerd als ‘vol’

of ‘leeg’

• Zodanig worden beheerd dat de oudste cilinders het eerst worden gebruikt

• Regelmatig op hun algemene toestand worden onderzocht

Personeel: (dat de opslagruimte betreedt) moet:

• Verantwoordelijk en competent zijn voor het bewaren van gascilinders en de inhoud ervan,

zoals hierboven beschreven

• Bekend zijn met de inhoud van gashouders en deze kunnen identificeren alsmede bekend

zijn met het mogelijke gevaar

3.1.2.NOODPROCEDURES:

Er kan een noodsituatie ontstaan door:

• Een brand in of in de buurt van de ruimte van het cilinderspruitstuk

• Een onbedoeld vrijkomen van gas uit cilinders of uit een pijpleiding

• Een ander mogelijk of daadwerkelijk incident dat gevolgen heeft voor de integriteit van de

spruitstukinstallatie

Te volgen procedure:

• Sla alarm en waarschuw een supervisor en/of bel de brandweer.

• Evacueer al het personeel uit de onmiddellijke gevarenzone.

Bij brand: verwijder alle cilinders:

• Sluit de cilinderklep(pen) op alle cilinders/cilinderbundels.

• Sluit de isolatieklep(pen) van de rij.

• Koppel de hogedrukslangen los.

• Verplaats de cilinders naar een veilige zone met gebruikmaking van een geschikte

cilindertrolley.

Bij het ongecontroleerd vrijkomen van gas:

• Open de deuren van de ruimte waarin zich het spruitstuk bevindt om de zone te ventileren.

• Breng geen ontstekingsbronnen in de ruimte.

Het is belangrijk dat iedereen te allen tijde vrije toegang heeft tot deze instructies en dat het

spruitstuk pas in gebruik wordt genomen nadat de operator zich volledig vertrouwd heeft

gemaakt met de functies, bedieningselementen en veiligheidsmaatregelen.

Alle werkgevers zijn verplicht, de benodigde informatie en training te verstrekken en toezicht

te houden volgens de nationale normen om de gezondheid en werkveiligheid van hun werk-

nemers te garanderen.

4. AANWIJZINGEN VOOR MEDEWERKERS

De Richtlijn Medische Hulpmiddelen 93/42/EEG bepaalt dat de product

aanbieder ervoor moet zorgen dat al het personeel dat met het product werkt de gebruiksaan-

wijzing en prestatiegegevens ontvangt.

Gebruik het product niet zonder de juiste vertrouwdheid met het product en de veilige werk-

ing zoals gedefi nieerd in deze Gebruiksaanwijzing. Zorg ervoor dat de gebruiker op de

hoogte is van specifieke informatie en kennis die vereist is voor het gebruikte gas.

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

Sidan laddas ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

på andra språk

- slovenčina: GCE Duplex Návod na používanie

- eesti: GCE Duplex Kasutusjuhend

- English: GCE Duplex Operating instructions

- dansk: GCE Duplex Betjeningsvejledning

Relaterade papper

-

GCE MC25 Bruksanvisningar

-

GCE MM90 SEMIAUTO Bruksanvisningar

-

GCE SIMPLEX MMR Bruksanvisningar

-

GCE PRESSURE WATCH Bruksanvisningar

-

GCE PRESSURE WATCH Bruksanvisningar

-

GCE THERAPY REG Bruksanvisningar

-

GCE MEDICONNECT Bruksanvisningar

-

GCE MMR Bruksanvisningar

-

GCE COMBILITE 10 YEARS Bruksanvisningar

-

GCE TERMINAL UNITS MINI Bruksanvisningar

Andra dokument

-

Nexa MTG-3000H Bruksanvisning

-

ESAB R-21 Regulator Användarmanual

-

Panasonic CUCZ35WKE Bruksanvisningar

-

Nexa MTG-3000H 12V / 230V GASSALARM Bruksanvisning

-

Panasonic CSHZ25WKE Bruksanvisningar

-

Panasonic CUNZ50VKE Bruksanvisningar

-

ESAB Precision Plasmarc System with Electronic Flow Control Installationsguide

-

Panasonic CUZ25UFEA1 Bruksanvisningar

-

Panasonic CUHZ25UKE Bruksanvisningar

-

Mitsubishi MSZ-HJ35VA Bruksanvisning