1

Motor Operating Device UEMC 40 A_, B_, D_

Moottoriohjain

Motormanöverdon

Installation, operating and recycling guide

Asennus-, käyttö- ja kierrätysohje

Monterings-, bruks- och återvinningsanvisning

22

Contents

1. General ............................................................3

2. Standards ........................................................3

3. Transport and storage ....................................3

4. Construction ....................................................3

5. General installation instructions .....................5

6. Examples of installation and basic

adjustment method .........................................6

7. Operation and locking ....................................10

8. Maintenance ....................................................10

9. Spare parts .....................................................10

10. Technical details .............................................11

11. Accessories .....................................................12

12. Range of models ............................................17

13. Instruction for recycling the product ..............23

14. Dimension drawing .......................................... 75

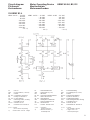

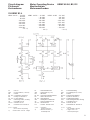

15. Circuit diagram ................................................ 76

Sisältö

1. Yleistä .............................................................. 27

2. Standardit ........................................................ 27

3. Kuljetus ja varastointi ....................................... 27

4. Rakenne .......................................................... 27

5. Asentaminen ............................................. 28

6. Erilliset asennusvaihtoehdot ja niiden

perussäädöt..................................................... 29

7. Ohjaus ja lukitus .............................................. 34

8. Huolto .............................................................. 34

9. Varaosat .......................................................... 34

10. Tekniset arvot .................................................. 35

11. Lisävarusteet ................................................... 36

12. Mallivalikoima .................................................. 41

13. Tuotteen kierrätys ...........................................47

14. Mittapiirros ....................................................... 75

15. Piirikaavio ........................................................ 76

Innehållsförteckning

1. Allmänt ............................................................ 51

2. Standarder ....................................................... 51

3. Transport och förvaring ................................... 51

4. Konstruktion .................................................... 51

5. Montering ........................................................ 52

6. Monteringsexempel, samt grund-

inställning ........................................................ 53

7. Manövrering och låsning ................................. 58

8. Service ............................................................ 58

9. Reservdelar ..................................................... 58

10. Tekniska värden .............................................. 59

11. Tilläggsutrustning ............................................ 60

12. Modellurval ...................................................... 65

13. Användning om produktens återvinning .......... 71

14. Måttritning........................................................ 75

15. Kretsschema ................................................... 76

3

a) Power transfer

Power is transfered from the motor through a gear

wheel and threaded shaft to the operating axel. The

direction of operation for open and close control can

be reversed by changing the motor’s direction of

rotation. The threaded shaft gear is assembled from

a round stainless steel shaft and one or two bronze

nuts. The shaft is self-locking which means that the

operating device cannot be rotated with a force from

the operating axel. This also applies if the operating

device is in the central position. The nuts transfer

the power through the specially formed lever to the

operating axel. The lever is formed so that it can be

locked in the extream position.

By disengaging the coupling ring, manual operation can

be performed by means of the control lever.

Both the gear wheel and the threaded shaft are

greased with low temperature grease which ensures

correct operation in temperatures as low as –50°C.

b) Mechanical locking

The unit is fi tted with a locking device which also

includes a switch to prevent the motor from operat-

ing. The locking unit mechanically locks the operating

device and is strong enough to withstand the driving

force of the motor if the blocking switch S12 fails. The

locking unit locks both the motor operating device and

the manual operating device.

c) Electrical operation

Motor operating device type UEMC 40 A1_, B1_,

and D1_ are fi tted with a lower level of electrical

components, and require a separate control unit, such

as UEZJ 1 or UEZJ 2.

Refer to circuit diagram: 31 UEMC 79.

Motor operating device type UEMC 40 A2_, B2_, and

D2-_are equipped with a complete control system

including contactors, I- and O-push buttons and m.c.b.

Refer to circuit diagram: 31 UEMC 81.

1. General

The UEMC 40 A_, UEMC 40 B_ and UEMC 40 D_ motor

operating devices are intended for indoor mounting on

medium voltage disconnectors and earthing switches.

The operating device is reliable in changing temperature

and humidity conditions.

Operation can be performed both electrically or by

means of the manual operating lever. Operating time

is about 5...8 s depending on the type of device and

loading conditions.

2. Standards

The motor operating device complies with

– IEC 265 (1983)

– VDE 0530 motor voltage test

3. Transport and storage

The motor operating device can be transported in any

position, and should be stored indoors in a dry area.

4. Construction

Fig. A

1. Power unit

2. Limit switch

3. Guide pin

4. Coupling ring

5. Locking catch

6. Motor

7. Terminal block

8. Control push button

9. M.c.b.

10. Contactor

11. Lever

12. Nut

44

5. General installation

instructions

This is a general description covering the installation of

a motor operating device. Refer also to point 6, examples

of installation and basic adjustment method.

Note

The motor operating device should not be operated

by driving the screw with a compressed air tool as this

could damage the motors gearwheel.

a) Install the disconnector, shaft and interlocking

between the disconnector and the earthing switch

Mount the elbow gear mechanism if the discon-

nector is to be mounted on the back wall of the

cubicle. Refer to installation instructions for the

disconnector, and also point 6.

b) Make the electrical connections to the motor ope-

rating device and earth the unit.

c) Fit the disconnector as detailed in the basic adjust-

ment instructions, point 6, examples of installation

on various disconnectors.

d) Test operate the motor operating device so that the

coupling ring A-4 is free and the unit is driven by

the motor, or by rotating the screw with a 19 mm

socket spanner. If the motor operating device

is driven by rotating the screw, ensure to stop

when the spring washer bigins to compress. Then

operate the disconnector from the shaft using

the handle, and make note of the position of the

coupling ring when the operating is complete.

The following criteria should be met both in open

and closed position:

– the shaft can be rotated to the point where

the coupling ring latches.

– a margin in the operating angle should be

available before the coupling ring A-4 latches.

e) Change the position of the motor operating mecha-

nism to another spline on the shaft by turning

if required, and repeat until the tolerance in the

control angle in both the open and closed posi-

tions is symetrical.

f) Electrically test operate the disconnector.

g) Tighten all locking bolts and nuts.

h) Check that the operating symbols are correct.

Symbols for anti-clockwise closed are included in

the delivery of UEMC 40 B_ and D_.

To change direction of operating for

UEMC 40 A1, B1 and D1:

Refer to circuit diagram: 31 UEMC 157

31 UEMC 161

Stick the left hand label to the coupling ring.

To change direction of operation for

UEMC 40 A2, B2 and D2:

– Swap connections X1:13 and X1:14,

red to X1:13 and brown to X1:14.

– Stick the left hand label to the coupling ring.

Note

Models UEMC 40 A1 and UEMC 40 A2 do not usu-

ally need to have their direction of rotation changed

as the direction of operation of the disconnector

can be chosen to suit by turning the larger toothed

gearwheel to the left or right side of the smaller

toothed gearwheel.

i) Select the right label for sticking on to the motor

operating device, according to language and method

of mounting. Label no. GB 3637-1 for push buttons

mounted above and label no. GB 3637-2 for push

buttons mounted below the operating shaft.

Connection of operating device to

a disconnector with an A-mechanism

The opening time for the A-mechanism operated with

the motor operating device is about 1 second. If a

quicker opening time is required, the A-mechanism is

to be fi tted with a tripping coil.

The tripping coil can be connected in parallel with

the opening circuit of the motor operating device which

gives:

– quick opening with tripping coil

– the motor operating device will start at the same

time as the tripping coil

– the motor operating device will be in the correct

position for the following closing operation

– the disconnector will be in the correct position for

earthing

– position indication laps will give both the discon-

nectors and the motor operating devices position.

5

6. Examples of installation and

basic adjustment method

A. NAL-disconnector mounted on

the rear wall of the cubicle

Spring device: A-mec, K-mec or KS-mec.

Fig. B

1. Motor operating device UEMC 40 A2- or UEMC 40 A1-

2. Joint UEMC-ZL 7

3. Adjuster coupling UEMC-ZL 10 (only for KS-mechanism)

4. Beveled gearwheel 53362/HE

5. Transmission tube 53346 (length 1,3 m)

53347 (length 2 m)

A-mec, basic adjustment method

1. Operating device in open position (as delivered).

2. Operate the disconnector in the direction of the

open position until the spring is charged, (charging

catch latches). Turn lightly using the handle, in the

direction of the arrow on the A-mechanism until the

free play is taken up.

3. Free the operating device's coupling ring A-4 for

manual operation, and turn the coupling ring so

that dimension X = 1 mm. Refer to fi g. B.

4. Install the motor operating device in this position.

5. Refer to point 5, general installation instructions.

K-mec, basic adjustment method

1. Operating device in open position (as delivered).

2. With the disconnector in the open position, lightly

turn using the handle, in the direction of the arrow

on the K-mechanism until the free play is taken

up.

3. Free the operating device’s coupling ring A-4 for

manual operation, and turn the coupling ring so

that dimension X = 6 mm. Refer to fi g. B.

4. Install the motor operating device in this position.

5. Refer to point 5, general installation instructions.

66

KS-mec, basic adjustment method

Applicable to both disconnector mounted on the side

or rear wall of the cubicle. Refer to fi g. B and fi g. C.

1. Operating device in open position (as delivered).

2. Disconnector in the closed position. Operate the

disconnector with the handle to charge the spring

device, and continue in the direction of the arrow

on the KS-mechanism until the free play is taken

up.

3. Loosen the adjuster coupling screws to max. free

play. The adjuster coupling provides facility to

adjust the extreme positions exactly and to reduce

the control angle.

4. Turn the adjuster coupling in the opposite direction

of the arrow KS-mec. until the free play is taken

up.

5. Install the motor operating device.

6. Tighten one adjustment screw on the adjuster

coupling until a light resistance is felt towards the

open position. Do not tighten it so much that the

coupling ring cannot be drawn out by hand. The

position of the adjuster coupling’s splines should

be that the adjuster screw is screwed out only a

few millimeters, otherwise the free play will not

be enough for positioning at the other end.

7. Trip the disconnector to the open position using

the tripping mechanism.

8. Free the operating device’s coupling ring A-4 and

operate the motor operating device to the

closed position, ensuring that the disconnector

remains in the open position. The operation can be

made electrically or by rotating the nut on top.

9. Operate the disconnector with the handle until the

closing spring is charged and the end free play

is taken up. If the coupling ring should not latch

in refer to above point 6.

10. Tight the adjuster couplings other adjustment screw

until a light resistance is felt towards the closed

position, but do not tighten so much that the

coupling ring cannot be drawn out by hand.

11. Trip the disconnector to the closed position using

the tripping mechanism.

12. Refer to point 5, general installation instructions.

7

B. NAL-disconnector mounted on the

side wall of the cubicle

Spring device: A-mec, K-mec or KS-mec.

The operating device can be mounted on the right hand

or left hand side of the disconnector. When mounted on

the right hand side it must be noted that the direction of

operation should be changed to anti-clockwise closed.

Refer to point 5.h.

Fig. C

1. Motor operation device UEMC 40 D2- or UEMC 40 D1-

2. Adjuster coupling UEMC-ZL 10 (only for KS-mechamism)

A-mec, basic adjustment method

1. Operating device in open position (as delivered).

2. Operate the disconnector in the direction of the

open position until the spring is charged, (charging

catch latches). Turn lightly using the handle, in the

direction of the arrow on the A-mechanism until

the free play is taken up.

3. Free the operating devices coupling ring A-4 for

manual operation, and turn the coupling ring so

that dimension X = 5 mm. See fi g. C

4. Install the operating device in this position.

5. Refer to point 5, general installation instructions.

K-mec, basic adjustment method

1. Operating device in open position (as delivered).

2. Disconnector in the open position. Turn lightly using

the handle in the direction of the arrow on the

K-mec until the free play is taken up.

3. Free the operating device's coupling ring A-4 for

manual operation, and turn the coupling ring so

that dimension X = 5 mm. See fi g. C.

4. Install the operating device’s in this position.

5. Refer to point 5, general installation instructions.

KS-mec, basic adjustment method

The same installation instructions are applicable to

disconnectors mounted on either the rear or side wall

of the cubicle. Refer to point 6.A.

88

C. ADNN-, or OJON- disconnectors

mounted on the rear wall of the cubicle

Fig. D

1. Motor operating device UEMC 40 A2- or UEMC 40 A1

2. Elbow gear mechanism UEMC-ZL 23 including:

– beveled gear wheel

– transmission tube 33 x 1500 mm

– joint

– extension shaft

1. Operating device in the open position (as deli-

vered).

2. Disconnector in the open position. Lightly turn,

using the handle, in the direction of the arrow until

the free play is taken up.

3. Mount the motor operating device.

4. Free the operating device's coupling ring A-4

and operate the motor operating device to the

closed position, ensuring that the disconnector

remains in the open position. The operation can

be made electrically or by rotating the screw.

5. Operate the disconnector with the handle to the

closed position. Take note of when the coupling

ring latches in. The coupling ring should latch in

when the disconnector is completely closed. Loosen

the connector from the operating mechanism and

rotate it to a suitable spline as required.

6. Open the disconnector using the handle and

repeat the above until the desired position is

obtained.

7. Refer to point 5, general installation instructions.

9

D. ADNN-, or OJON- disconnectors

mounted on the side wall of the

cubicle

The operating device can be mounted on either the

left hand or right hand side of the disconnector. When

mounted on the left hand side it must be noted that

the direction of operation should be changed to anti-

clockwise closed, refer to point 5.h.

Fig. E

1. Motor operating device UEMC 40 B2-, or UEMC 40 B1

2. Adjuster coupling UEMC-ZL 9 for round shaft Ø 25

UEMC-ZL 10 for splined shaft Ø 25

3. Extension shaft UEMC 242 fi t to adjuster coupling UEMC-ZL 10

1. Operating device in open position (as delivered).

2. Loosen the adjuster coupling screws to max. free

play. The adjuster coupling provides facility to

adjust the extreme positions exactly and to reduce

the control angle.

3. Disconnector in open position.

4. Turn the coupling adjuster and the disconnector

lightly in the direction of the arrow until the free

play is taken up.

5. Install the motor operating device.

6. Tighten one adjustment screw on the adjuster

coupling until the disconnector turns lightly against

the open stopper. The position of the adjuster

coupling's splines should be that the adjuster

screw is screwed out only a few millimeters, other-

wise the free play will not be enough for positioning

at the other end. Change the adjuster coupling to

another spline if required.

7. Free the operating device’s coupling ring A-4

and operate the motor operating device to the

closed position, ensuring that the disconnector

remains in the open position. The operation can

be made electrically or by rotating the nut.

8. Operate the disconnector with the handle to the

closed position.

9. Tighten the adjuster coupling's other adjustment

screw until the disconnector turns lightly against

the close stopper.

10. Test operate and adjust the adjustment screws if

necessary.

11. Refer to point 5, general installation instructions.

1010

7. Operation and locking

a) Motorized operation

– Switch the “MOTOR”-switch to the ON position.

In this position both the local and remote

functions operate.

– Use the control pushbuttons I or O for local

control.

b) Manual operation

Switch the “MOTOR”-switch to the OFF-position.

Pull the coupling ring out and operate using the control

handle. Some disconnectors will need a slight turn in

the other direction with the control lever before the

coupling ring A-4 can be pulled out. See also acces-

sories UEMZ 469.

c) Motorized operation after manual

operation

After manually operating the disconnector once, the

power unit is not in synch with the disconnector. The

coupling ring A-4 usually drops into place itself when

next using the motor operating device. To assist the

coupling ring relocating itself, turn the axel slightly

backwards after manually operating the disconnector.

If for example the disconnector is opened manually

and then it is to be closed using the motor operating

device, fi rst drive the motor operating device to the

open position so that the coupling ring drops into place

and then drive it to the closed position.

d) Mechanical locking

Switch the “MOTOR” -switch to the O-position. The

disconnector can be locked when the motor operat-

ing device is in the open or closed position, also after

manual operation, even if the coupling ring is disengaged.

Lock after pushing the locking catch A-5 in using

∅ 6...10 mm padlock. The locking will also open the

electrical operating circuit automatically.

8. Maintenance

The operating devices threaded shaft and gearwheel

is to be greased at 5 year intervals or after 1000 ope-

rations.

Recommended grease type is Isofl ex Topas NCA 52

or similar synthetic low temperature resistant grease.

The grease can be ordered from the manufacturer of

the operating device.

If the operating device is fi tted with an anti-conden-

sation heater check that it works.

9. Spare parts

When ordering spare parts all details on the rating plate

are to be mentioned.

Spare parts Type Remarks

Motor + gear wheel UEZM 5/U/3 U = Voltage

Motor gear wheel J403323

Diode SK 1/16

Rectifi er - REC 36 MB 160 A

Limit switch S1, S2 OYAX 13

Contactor K1, K2 - ABB VBC 6-30-01/U U = Voltage

Relay K3 - RFI 40.52.9.048

11

10. Technical details

– Direction of operation:

clockwise to close easily changeable, see point 5.h.

– Motor: Rectifi ed DC, permanent magnet type

Rated voltage Normal control current Max. current Recommended

U/V In/A Imax/A M.c.b.

24 VDC 12 40 - S202 K8

48 VDC 6 20 - S202 K4

60 VDC 5 17 - S202 K4

110 VDC 2 5.5 - S202 K2

125 VDC 2 5.5 - S202 K2

220 VDC 1 3 - S282 UCK 1

230 VAC 1 3 - S202 K1

– Manual operating device with operating handle

UEKO-ZK 1

– Terminal block 6 mm

2

– Anti-condensation heater 5 W

(to be ordered separately)

– Operating time at standard load 5...8 s

Operating time at different load

1) With accessory: Coupling ring UEMZ 452

UEMC 40 UEMC 40 UEMC 40

A1 A2 B1 B2 D1 D2

Torque Nm 200 200 300 300 200 200

Weight kg 14.5 14.5 12.5 12.5 13 13

Contactors:

Closing power W 3 3 3 3 3 3

Holding power W 3 3 3 3 3 3

Shortest control pulse s 0.1 0.1 0.1 0.1 0.1 0.1

Operating angle Degr. 190 190 110 110 150 150

Degr. 210 1) 210 1)

1212

11. Accessories

Operating handle UEKO-ZK 1 or

HE 53235

The operating handle is insulated and fi tted with an

insulated grip.

Extension shaft UEMC -ZL 24

Includes:

– shaft 240 mm (splined)

– extention socket 70 mm (splines to splines)

The shaft have cutting grooves at regular inter vals.

∅ 25 splined / ∅ 25 splined

Protective m.c.b.

Used to connect the supply circuit and protect the motor

agai nst over lo ading.

Auxiliary contact for m.c.b.

– STOS2C-S/H6R

Includes 2 pcs. change-over con tacts.

splined

Coupling ring UEMZ 452

Increases the operating angle to 210

o

for motor

operating devices UEMC 40 A_

Motor voltage Miniature circuit breaker type

24 VDC - S202 K8

48 VDC - S202 K4

60 VDC - S202 K4

110 VDC - S202 K2

125 VDC - S202 K2

110 VAC - S202 K2

220 VDC - S 282 UCK 1 / STO S2 - S / H

230 VAC - S202 K1

13

Operating box UEZJ 2-

1) Type UEZJ 1-UU is to be ordered when different motor and

auxiliary voltages are to be used. Please give details of the

voltages when ordering.

1) Type UEZJ 1-UU is to be ordered when different motor and

auxiliary voltages are to be used. Please give details of the

voltages when ordering.

1) Type UEZJ 2-UU is to be ordered when different motor and

auxiliary voltages are to be used. Please give details of the

voltages when ordering.

Control unit UEZJ 1-

Control unit UEZJ 1- /2

Type Circuit diagram

UEZJ 2 - 24 VDC 31 UEMC 148

UEZJ 2 - 48 VDC "

UEZJ 2 - 60 VDC "

UEZJ 2 - 110 VDC "

UEZJ 2 - 125 VDC "

UEZJ 2 - 220 VDC "

UEZJ 2 - 110 VAC "

UEZJ 2 - 230 VAC "

UEZJ 2 - UU

1) 31 UEMC 149

Type Circuit diagram

UEZJ 1 - 24 VDC 31 UEMC 148

UEZJ 1 - 48 VDC "

UEZJ 1 - 60 VDC "

UEZJ 1 - 110 VDC "

UEZJ 1 - 125 VDC "

UEZJ 1 - 220 VDC "

UEZJ 1 - 110 VAC "

UEZJ 1 - 230 VAC "

UEZJ 1 - UU 1) 31 UEMC 149

Type Circuit diagram

UEZJ 1 - 24 VDC/2 31 UEMC 141

UEZJ 1 - 48 VDC/2 "

UEZJ 1 - 60 VDC/2 "

UEZJ 1 - 110 VDC/2 "

UEZJ 1 - 125 VDC/2 "

UEZJ 1 - 220 VDC/2 "

UEZJ 1 - 110 VAC/2 "

UEZJ 1 - 230 VAC/2 "

UEZJ 1 - UU/2 1) 31 UEMC 142

1414

Control push buttons UEZJ 3

Includes:

– I -button, with text: CLOSE

– O -button, with text: OPEN

– On/Off selector switch,

with text: REMOTE ON/OFF

Set of indicator lamps UEZJ 4

Type: UEZJ 4 - 24 V

- 48 V

- 60 V

- 110 V

- 125 V

- 220 VDC

- 230 VAC

Includes: red, green, and yellow lamps.

The same type for both DC and AC.

Adjuster coupling UEMC-ZL 9

Provides facility to adjust the extreme positions exactly

and to reduce control angle steplessly max 30°.

∅ 25 splined / ∅ 25

Adjuster coupling UEMC-ZL 10

Provides facility to adjust the extreme positions exactly

and to reduce control angle steplessly max 30°.

∅ 25 splined / ∅ 25 splined

OPEN

CLOSED

REMOTE

ON/OFF

Splined

Splined

Splined

15

Joint UEMC-ZL 7

For transmitting the operating movement through an

angle of max 40°.

For tube diameter: 3/4" (26.9 mm)

Splined

Joint UEMZ 390

For transmitting the operating movement through an

angle of max 40°.

For tube diameter: 1" (33.7 mm)

Extension shaft UEMZ 242

∅ 25 splined / ∅ 25

Elbow gear mechanism UEMC-ZL 23

Includes:

UEMZ 404: Beveled gear wheel

UEMZ 390: Joint

UEMZ 242: Extension shaft

UEMZ 403: Transmission tube ∅ 33.7 x 1500 mm

Tube length = A – 150 mm

Splined

Splined

Splined

1616

Manual operation by means of an

insulated staff

Contents:

1. Screw extensions UEMZ 469

2. Conical adapter – RAG MGA 87

3. Operating rod – RAG MTG 201-K

Length 6390 mm

Function:

The conical adapter can be fi tted on the end of an

insulated staff as used for changing fuses on pole

mounted transformers. Manufactured by Melby or

Ragnar Stålskog. By turning the staff, the operating

mechanism can be controlled.

Mechanism OJO-ZB 1 (alternative to UEMC-ZL 23)

17

12. Range of models

NAL_

OJD_

UEMC 40 A_

UEMC 40 A_

UEMC 40 A_

UEMC 40 A_

Disconnector

Joint

UEMC-ZL 7

Elbow gear mec.

UEMC-ZL 23

Elbow gear mec.

UEMC-ZL 23

Elbow gear mec.

UEMC-ZL 6

ADNN 52 kV

ADNN 72.5 kV

OJON_

ADNN 12-24 kV

Coupling ring

UEMZ 452

Coupling ring

UEMZ 452

Disconnector mounted on the rear wall of cubicle

Disconnector

Motor operating device

Important accessories

NAL_

OJON_

ADNN_

OJD_

Extension shaft

UEMC-ZL 24

Extension shaft

UEMC-ZL 5

UEMC 40 B_

UEMC 40 B_

UEMC 40 D_

Disconnector mounted on the side wall of cubicle

Adjuster coupling

UEMC-ZL 9

Adjuster coupling

UEMC-ZL 10

Extension shaft

UEMZ 242

Important accessories

Motor operating device

34 UEMC 36_

34 UEMC 36_

34 UEMC 36_

34 UEMC 28_

Guide

Guide

34 UEMC 36_

34 UEMC 28_

34 UEMC 36_

1818

UEMC 40 A_, B_, D_

Earthing switch mounted on the rear wall of cubicle

Earthing switch Accessories

UEMC 40 A_

34 UEMC 36_

ADJ_

OJO-ZMA_

OJWM_

Elbow gear mec.

UEMC-ZL 23

UEMC 40 A_

34 UEMC 36_

OJWN_

OJD-ZM_

Elbow gear mec.

UEMC-ZL 6

34 UEMC 36_

E for NAL

EB for NAL

Joint

UEMC-ZL 7

UEMC 40 A_

Motor operating device Guide

Earthing switch mounted on the side wall of cubicle

Earthing switch

Accessories

UEMC 40 B_

Extension shaft

UEMZ 242

ADJ_

OJO-ZMA_

OJWM_

Adjuster coupling

UEMC-ZL 10

Adjuster coupling

UEMC-ZL 9

Guide

34 UEMC 36_

UEMC 40 B_

OJWN_

OJD-ZM_

Extension shaft

UEMC-ZL 5

34 UEMC 28_

UEMC 40 D_

E for NAL

EB for NAL

34 UEMC 36_

Motor operating device

Extension shaft

UEMC-ZL 24

19

Control unit

UEZJ 1 - 24 VDC

- 48 VDC

- 60 VDC

- 110 VDC

- 125 VDC

- 220 VDC

- 110 VAC

- 230 VAC

- UU

Operating box

UEZJ 2 - 24 VDC

- 48 VDC

- 60 VDC

- 110 VDC

- 125 VDC

- 220 VDC

- 110 VAC

- 230 VAC

- UU

Adjuster coupling

UEMC-ZL 10

only for KS-mec.

Operating handle

UEKO-ZK 1 or

HE 53235

Disconnector

NAL_

NALF_

Joint

UEMC-ZL 7

Motor operating device

UEMC 40 A2 - 24 VDC

- 48 VDC

- 60 VDC

- 110 VDC

- 125 VDC

- 220 VDC

- 110 VAC

- 230 VAC

- UU

Motor operating device

UEMC 40 A1 - 24 VDC

- 48 VDC

- 60 VDC

- 110 VDC

- 125 VDC

- 220 VDC

Control push

buttons

UEZJ 3

UEMC 40 A_

Disconnector mounted on the rear wall of cubicle

Protective m.c.b.

- S202 K8 for 24 V

- S202 K4 for 48 V

- S202 K4 for 60 V

- S202 K2 for 110 V

- S202 K2 for 125 V

- S202 K1 for 230 VAC

- S282 UCK 1 for 220 VDC

Aux. contacts for m.c.b.

– STOS2C-S/H6R

Set of

indicator lamps

UEZJ 4 -24 V

- 48 V

- 60 V

- 110 V

- 125 V

- 220 VDC

- 230 VAC

2020

Disconnector

NAL_

NALF_

Adjuster coupling

UEMC-ZL 10

only for KS-mec.

Operating handle

UEKO-ZK 1 or

HE 53235

UEMC 40 D_

Disconnector mounted on the side wall of cubicle

Motor operating device

UEMC 40 D2 - 24 VDC

- 48 VDC

- 60 VDC

- 110 VDC

- 125 VDC

- 220 VDC

- 110 VAC

- 230 VAC

- UU

Motor operating device

UEMC 40 D1 - 24 VDC

- 48 VDC

- 60 VDC

- 110 VDC

- 125 VDC

- 220 VDC

Operating box

UEZJ 2 - 24 VDC

- 48 VDC

- 60 VDC

- 110 VDC

- 125 VDC

- 220 VDC

- 110 VAC

- 230 VAC

- UU

Control unit

UEZJ 1 - 24 VDC

- 48 VDC

- 60 VDC

- 110 VDC

- 125 VDC

- 220 VDC

- 110 VAC

- 230 VAC

- UU

Protective m.c.b.

- S202 K8 for 24 V

- S202 K4 for 48 V

- S202 K4 for 60 V

- S202 K2 for 110 V

- S202 K2 for 125 V

- S202 K1 for 230 VAC

- S282 UCK 1 for 220 VDC

Aux. contacts for m.c.b.

– STOS2C-S/H6R

Control push

buttons

UEZJ 3

Extension shaft

UEMC-ZL 24

Set of

indicator lamps

UEZJ 4 -24 V

- 48 V

- 60 V

- 110 V

- 125 V

- 220 VDC

- 230 VAC

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

Sidan laddas...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88